Executing Expected Goods Receipts Processes

The GRN is issued to the supplier only if the goods match the description in the documents. Warehouse operations have been transformed by GRNs, with managers reporting improved stock control and reduced overstocking or stockouts. A case study from a multinational retail chain highlighted a 25% improvement in inventory turnover ratio post-GRN implementation. Finally, the performance of both the supplier and the procurement process is evaluated to identify areas for improvement. The requisition is then reviewed by different stakeholders, often including goods received note the finance department, to ensure it aligns with the budget and company policy.

- It acts as a verification tool, confirming that what was ordered has indeed arrived, and in the right condition and quantity.

- It ensures accurate record-keeping, supplier verification, and efficient inventory management.

- Modern GRN automation software uses Optical Character Recognition (OCR) to extract information from paper forms or PDF delivery notes.

- The final step involves sharing the GRN with the finance and procurement departments.

- A Service Received Note (SRN) or Service Entry Sheet (SES) serves the same purpose but for intangible services, confirming that a contracted service was performed to the agreed-upon standard.

EnFin: Your Fresh Source of Fintech Updates (January 2026 Edition)

Therefore, understanding these errors and implementing robust checks and balances is paramount for maintaining an accurate stores ledger. The implementation of Goods Received Note (GRN) systems has revolutionized the procurement cycle, offering a robust framework for verifying contra asset account and documenting the receipt of goods. By integrating GRN protocols, organizations have witnessed a significant enhancement in operational efficiency, reduction in discrepancies, and improvement in supplier relationships.

Role of GRN in Inventory Management

- It keeps accurate records and supports procurement and financial processes.

- It also acts as a communication bridge between different departments, such as procurement, warehouse, and finance, helping streamline operations and prevent discrepancies.

- Furthermore, having a proper GRN system improves communication across departments, reducing delays and enhancing overall efficiency in the supply chain.

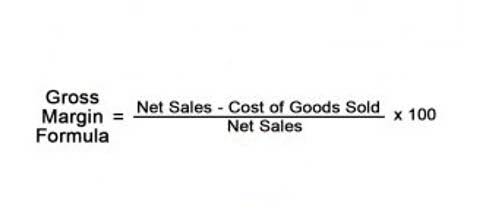

- If all three records (PO, GRN, and invoice) match, then the invoice is authorized for payment, helping to prevent the payment of incorrect amounts.

- That’s why optimizing the Goods Received Note (GRN) process isn’t just an efficiency upgrade, it’s a necessity for any organization that wants better control, accuracy, and cost savings in procurement.

- A GRN serves as evidence that both the supplier and the customer have adhered to the terms of their agreement.

It is digital software that streamlines all your organization’s processes from enquiry to dispatch so that you can keep your GRN-related worries aside. To solve this, manufacturers have started using automation software that manages all your GRN requirements. Software automates everything from purchase and inventory to sales and quality assurance. A material receipt note is a record of what has been received in deliveries of the supplies ordered. The GRN helps to keep track of the inventory and fastens the entry of goods to the warehouse.

Payments

If an error is made in a goods received receipt, it can cause mismatches in stock levels, incorrect payments to suppliers, or even disputes between buyers and suppliers. A goods receipt note is a document used in businesses to confirm that goods have been received from a supplier. This helps keep track of received goods, ensuring that the correct quantity and quality match the purchase order. In accounting, a Statement of Comprehensive Income GRN verifies supplier invoices, ensuring payments align with received goods.

It acts as a checkpoint between suppliers and buyers, ensuring accountability and alignment with purchase orders (POs). Traditionally, GRNs have been paper-based, but digital transformation is reshaping their role, integrating them into ERP systems, blockchain platforms, and AI-driven workflows. The GRN is not just a document; it’s a critical communication tool that bridges the gap between receiving dockets and the company’s inventory system.

Reserving dock space, scheduling inspectors, and syncing inventory systems with ASN data.

With features such as automated workflows and integration capabilities, Manifestly can help ensure that your inventory management is both efficient and accurate. Explore more about how to streamline your inventory processes with Manifestly by visiting our guide to workflow management software. Understanding how a Goods Received Note functions in real-world scenarios can be incredibly beneficial for operations managers looking to optimize their processes. Real-world examples of effective GRNs demonstrate how businesses have successfully implemented these documents to enhance their operations. These examples illustrate the practical application of a GRN, showing how it can resolve discrepancies, improve supplier relationships, and maintain accurate inventory records. A well-designed GRN process ensures that the received goods are accurately recorded in your inventory management system.

Managing inventory & updating stock levels

By promptly updating stock levels upon receiving goods, you reduce the risk of stockouts or overstocking, enabling better inventory control and decision-making. A Goods Received Note (GRN) is a document that confirms goods have been received from a supplier. It records the quantity and quality of the items, ensuring they match the purchase order. The primary purpose of a GRN is to provide official internal proof that a delivery has been received. This critical document enables accurate three-way invoice matching, ensures inventory records are updated correctly, and creates a clear audit trail for financial verification and dispute resolution. GRNs ensure accurate inventory records by updating stock levels when goods are received.